BF-1160V 4 axis vertical machining center

Table: 1200*600mm

Travel: 1100*650*650mm

Guideway: X/Y/Z axis linear way

High speed high precision VMC for molds processing

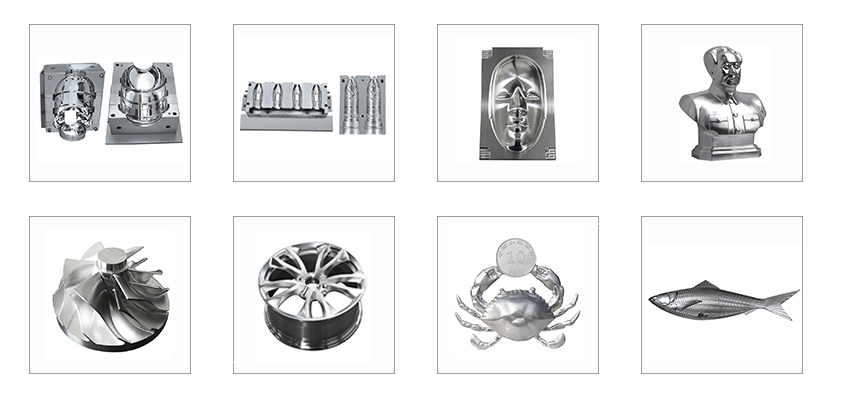

BF-1160V adopts optimized C-type structure with gold proportion design, has super machine rigidity and stability. It is featured for high speed and high precision processing, mainly used in high precision and high efficient processing of medium and small molds, could be broadly applied in the industry of automobiles, machinery, instrumentation, light industrial textiles, electronic instruments, can fully present high precision and high-efficiency machining ability at a very reasonable cost.

| Parameter | Unit | BF-1160V |

| X/Y/Z axis travel | mm | 1100*650*650 |

| Table size | mm | 1200*600 |

| T slot | mm | 5-18*100 |

| Max load on table | kg | 800 |

| Spindle center to column | mm | 658 |

| Spindle nose to table | mm | 130-780 |

| X/Y/Z axis motor | KW | 3.0/3.0/3.0 |

| X/Y/Z rapid feed | m/min | 30/30/30 |

| Controller | Mitsubishi M80A/M80B Fanuc: 0i-MF/Siemens 828D | |

| Spindle taper | BBT40 | |

| Spindle speed | rpm | 12000 |

| Spindle motor | 11kw | |

| Positioning accuracy | mm | ±0.003/300 |

| Repeated accuracy | mm | ±0.002/300 |

| Air pressure | kg/cm² | 6~7bar |

| Dimension | mm | 3170x3200x3320 |

| Weight | kg | 6500 |

- Special design for high speed and high accuracy molds processing, with great performance in semi-finishing and finishing processing.

- Special large span structure of the machine base and column, is able to bear high inertia gravity and improve dynamic responsiveness of the whole machine.

- Top brand BBT40 spindle, adopt ceramic bearing, rigidity and surface smoothness is higher performance than BT ball bearing.

- V1 vibration standard of BBT40 direct drive spindle, compared with most popular V4 vibration standard, has smaller spindle vibration and better surface processing performance.

.jpg)

◆Kindly notice that configuration and appearance are subject to fine products.

|

Item |

Name |

|

1 |

Mitsubishi M80B controller system |

|

2 |

BBT40 12000rpm direct drive spindle |

|

3 |

11kw 12000rpm spindle motor |

|

4 |

Spindle blowing system |

|

5 |

Spindle oil cooler |

|

6 |

Automatic centralized lubrication system |

|

7 |

Pneumatic system |

|

8 |

Coolant flushing system |

|

9 |

Heat exchanger for electrical cabinet |

|

10 |

Rear chip-removal device |

|

11 |

Operation manuals |

|

12 |

Alarming light |

|

13 |

Work light |

|

14 |

Full enclosed cover |

|

15 |

Guideway cover |

|

Item |

Name |

|

1 |

Mitsubishi M80A controller system |

|

2 |

Fanuc 0i-MF controller |

|

3 |

Siemens 828D controller |

|

4 |

15000rpm BBT40 spindle |

|

5 |

Coolant through spindle |

|

6 |

BT40-24T arm type chip conveyor |

|

7 |

Chain type chip conveyor |

|

8 |

4th axis rotary table |

.jpg?imageView2/1/w/400/h/400/q/80)

Strengthened cross-ribs to increase bending and torsion resistance.

.jpg?imageView2/1/w/400/h/400/q/80)

Box structure large span A type column with high rigidity to ensure stability during machining.

.jpg?imageView2/1/w/400/h/400/q/80)

Base

Double layered box type base to ensure high stability and rigidity.

.jpg?imageView2/1/w/400/h/400/q/80)

Double T extra-wide structure to improve rigidity and stability during rapid feed.

.jpg?imageView2/1/w/400/h/400/q/80)

Box structure spindle head to increase cutting rigidity, improve the machining efficiency.

.jpg?imageView2/1/w/400/h/400/q/80)

3 axis ball/roller linear guideway, rapid feed is 48m/min.

.jpg?imageView2/1/w/400/h/400/q/80)

X / Z axis guideway 3 sliders to increase the stability and accuracy during machining.

.jpg?imageView2/1/w/400/h/400/q/80)

C3 grade high precision ball screw with pre-extension process, improve the transmission rigidity and machine accuracy.

.jpg?imageView2/1/w/400/h/400/q/80)

Belt/direct drive spindle with spindle oil coolant and blowing system to ensure spindle precision and stability under high speed running.

.jpg?imageView2/1/w/400/h/400/q/80)

Mitsubishi/Fanuc/Siemens controller system optional.

4 Axis Machining Center, 4 Axis Machine

Buy 4 Axis Machine at Reasonable prices

Are you looking to buy the 4 Axis Machining Center in bulk? Baofengmachine.com provides the top quality 3 axis and 4 Axis Machining Center at reasonable prices. We have established our presence with a motto to be the first choice for a wide range of clients. With the 4-axis CNC machining center, we can satisfy the client's needs.

Features of 4 Axis Machining Center:

- Reliable to use

- Affordable

Buy now the top quality 4 Axis Machine made in China!